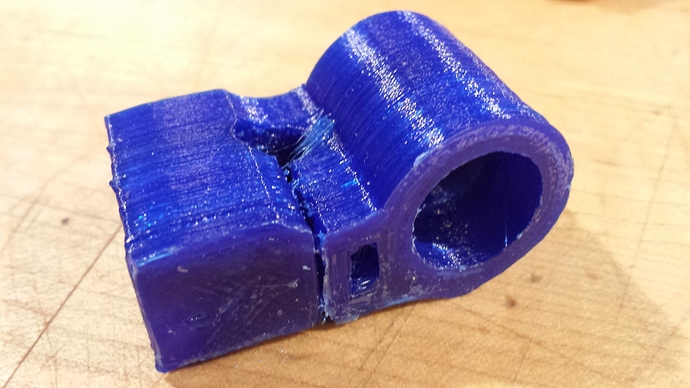

2:05 print, 160 layers, no failures, 100% infil, no retraction. Which makes sence, it printed vases okay, and hollow squares…It’s even reasonably dimensionally correct. (Correct enough that I’ll run a drill through it and call it good.)

Why on earth are you printing at total infill?

I print at 100% infill all the time. In fact all of the parts for my printer are printed at 100%. It provides stability and strength, great layer adhesion, and super thermal properties.

if I was printing a figure or a toy, I would do less, but when you need strength and durability I print at the max.

I am using 40% infill for printer parts, 2mm shell sickness.

If you need extra strenght next time I would just increase the number of perimeters vs 100% unfill.

Sometimes your actually making a part more liable to fail by doing 100% infill. Some parts need to flex

When I do 100% infill with ABS, my part is more likely to warp and peel from the heated bed. Nice looking part tho

Hey mike, I’ve just gone back through and seen all your posts, all the time not realising that there’s an E3Dv5 in the middle of this whole affair. The shame! Can you get in touch with me via the contact form on our website so we can support you directly?

Certainly!

The 100% infil was to reduce the number of retracts in the closest part I had in my library to test the theory that it was the retractions that were causing my problems. I’d love to reduce that somewhat, if only to save some filament and time.

Yey